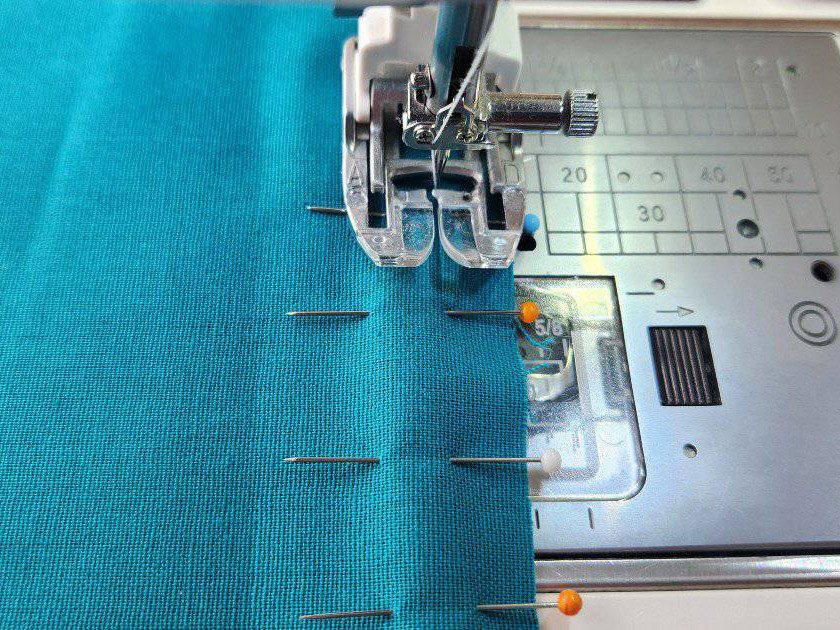

In apparel manufacturing, even small tools create big outcomes. At Xzapparel, our team handles every fabric type from fine voile to thick denim—and we depend on different pins to make production flow smoothly. But not all pins are created equal.

The main difference is that quilting pins are longer and thicker for layered, heavy fabrics, while sewing pins are finer and shorter, designed for everyday garment assembly.

Understanding how and when to use each pin style ensures better accuracy and fabric safety.

How do quilting pins and sewing pins differ in size?

Length and thickness define their use.

Quilting pins are usually 1.75 to 2 inches long with a 0.6–0.7 mm shaft. Sewing pins are shorter, about 1.25 to 1.5 inches, and thinner—usually 0.5 to 0.6 mm.

Size Comparison Table

| Pin Type | Typical Length | Typical Thickness | Best Used For |

|---|---|---|---|

| Quilting Pin | 1.75″–2″ | 0.6–0.7 mm | Multi-layered, padded fabric |

| Sewing Pin | 1.25″–1.5″ | 0.5–0.6 mm | Woven, light to medium knits |

Longer pins help stabilize thicker seams; shorter pins maintain fine edge control.

What fabrics are suitable for each pin type?

Match the pin to the material.

Quilting pins work best for cotton batting, quilt sandwiches, denim, canvas, or thick knits. Sewing pins are best for poplin, rayon, jersey, or lining.

Fabric Guide

| Fabric Type | Recommended Pin Type |

|---|---|

| Cotton (quilting) | Quilting Pin |

| Polyester Crepe | Sewing Pin |

| Denim | Quilting Pin |

| Viscose | Sewing Pin |

| Wool blends | Quilting Pin |

| Light jersey | Sewing Pin |

We stock both pin types at every workstation for fast switching.

What about pinheads and usability?

Grip and visibility matter.

Quilting pins often feature large plastic ball heads for easier handling, while sewing pins might have flat, glass, or small ball heads.

Head Type Differences

- Quilting Pins: Bigger heads, often color-coded

- Sewing Pins: Smaller heads, flatter profiles, sometimes glass

At Xzapparel, we use quilting pins with flower heads during jacket interfacing and sewing pins with glass heads for collar builds.

Are there differences in flexibility and strength?

Yes—and it impacts durability.

Quilting pins are slightly more rigid to avoid bending in dense layers, while sewing pins offer moderate flexibility to adapt to curved seams.

Strength Differences

| Pin Type | Strength | Bend Resistance | Purpose |

|---|---|---|---|

| Quilting Pin | High | Strong | Keeps multiple thick layers aligned |

| Sewing Pin | Medium | Moderate | Best for light to mid-weight seams |

Incorrect usage (e.g., using sewing pins on canvas) leads to bending, broken pins, or fabric distortion.

What are common use cases in apparel manufacturing?

Context matters.

We use quilting pins during outerwear builds, structured seam reinforcements, or when layering linings with stiff interfacings. Sewing pins dominate in dress and blouse production.

Pin Usage by Department

| Department | Pin Type | Use Example |

|---|---|---|

| Cutting Room | Sewing Pin | Anchoring silk or viscose layers |

| Outerwear Station | Quilting Pin | Securing batting and heavy interlining |

| Shirt Line | Sewing Pin | Precise collar seam positioning |

| QC Desk | Quilting Pin | Reinforcing panels for fitting review |

We train all sample makers on pin substitution strategies.

What about ironing safety?

Watch the head material.

Glass-head pins are used when pressing is required—common in both pin types. Plastic heads may melt under heat.

We use high-heat glass pins during pre-sew ironing and restrict plastic heads to post-press steps.

Storage and magnetic control protocols

Stay organized.

Quilting pins often come in boxes with foam or magnetic sheets; sewing pins are stored in magnetic dishes or color-coded jars.

Our Factory SOPs

- Always separate quilting and sewing pins

- Use red dishes for quilting, blue for sewing

- Return all pins post-session to avoid machine interference

Misplaced pins can cause needle breaks or poor QC results.

When is it okay to substitute one for the other?

Rarely—but possible.

In urgent cases, you can use quilting pins for sewing, but sewing pins should not be used for thick material—it causes distortion.

Substitution Rules

- Use quilting pins cautiously on fine silk—risk of hole damage

- Use sewing pins on denim only if stitching stress is minimal

We mark pin substitution approvals on our internal production tickets.

Conclusion

Quilting pins and sewing pins each serve unique roles in apparel production. Their difference in length, thickness, flexibility, and usability reflects the needs of layered vs. fine garment construction. At Xzapparel, knowing when and how to use each is key to maintaining quality and efficiency.

Need production-ready garment pinning and prep systems tailored for your product line? Let’s make your sampling process seamless.